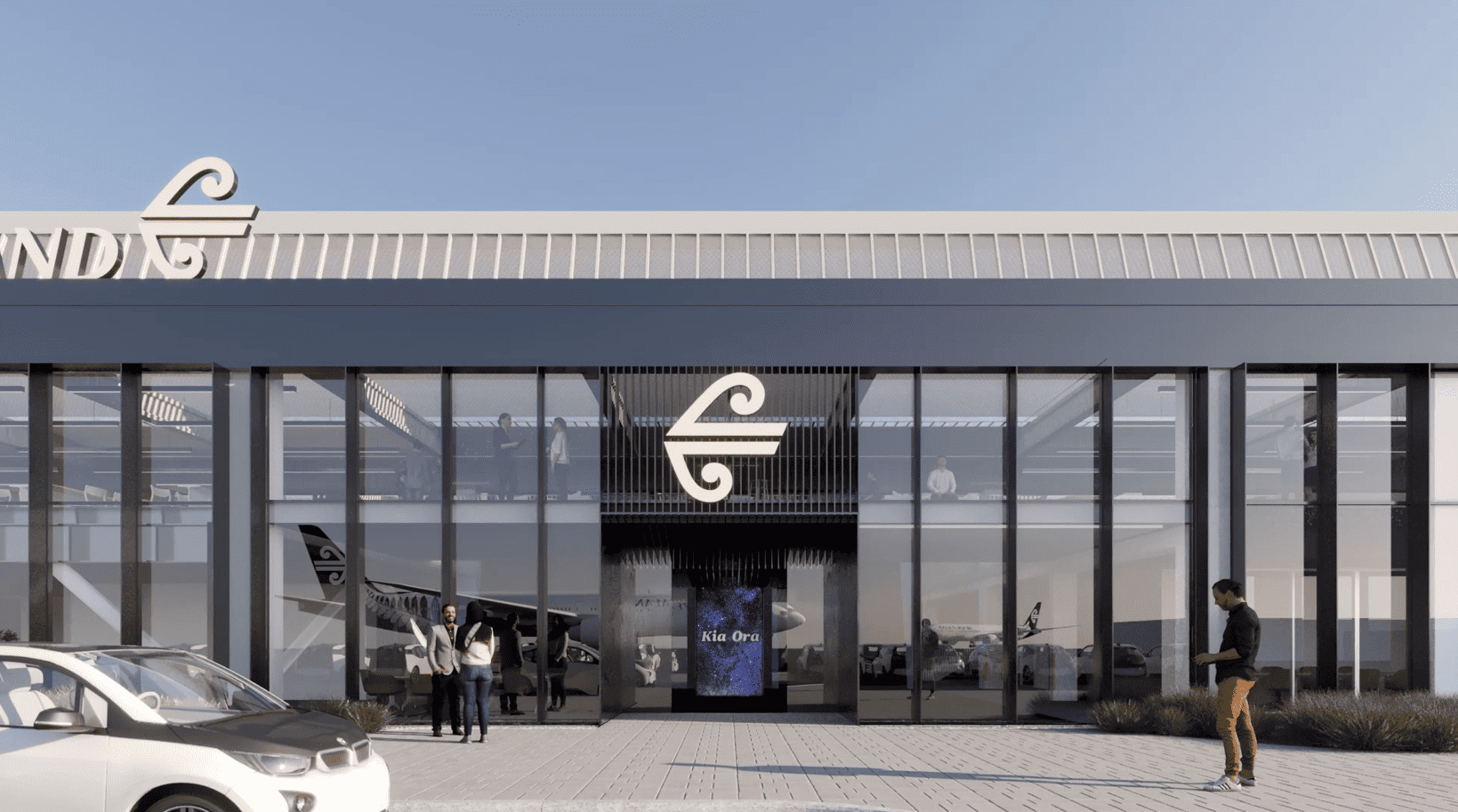

Air New Zealand will bring its central Auckland team into the heart of its operation, future-proofing its infrastructure and reducing its property costs via a multi-year investment at its Auckland airport base. The airline will begin building a new aircraft hangar and has approved in-principle a project to centralise its Auckland workforce at a refurbished airport campus.

The four-year investment will create a world-class aviation facility for Air New Zealand employees and its aircraft as the airline rebuilds. Air New Zealand Chief Executive Officer Greg Foran says this dual investment is part of its long-term strategy to unleash the airline’s full potential.

“We’ve spent the last two years looking at how we can set ourselves up for success as we revive our airline. We know we work best when we work together, and we have plenty of underutilized space at the airport campus to make that happen. We’ll be creating an environment where the people who plan our future work alongside those who operate our aircraft and work with our customers every day. Globally, this way of working is delivering exceptional results for customers and shareholders, and this is the right time to get ready for a move as we prepare for the global recovery in aviation,” he said.

The majority of Air New Zealanders are based in Auckland and it’s expected they’ll move to the airport campus in 2024. Moving the city office to the airport will consolidate office space, significantly reducing the airline’s property footprint, and reducing costs by 20% over 15 years. After design and construction phases, the move is likely to occur in 2024.

The new 10,000m2 engineering facility – called Hangar 4 – was first announced in 2019 and will be world-leading in sustainability, with a 6-star green rating and the largest single span timber arch aircraft hangar in the Southern Hemisphere.

“We’re confident that our long-haul operation will return so investing now in a new Hangar that will be large enough to house a 787 and two A320s side-by-side in one space makes complete sense. It’s also been designed by our engineering and maintenance employees to ensure it’s suitable for them and the work they need to do. Our existing hangars were built in the 1960s and 1980s and, while they have served us well, our fleet has changed over the decades. We now have a need for a more modern, innovative structure that takes energy use and other sustainability factors into account.”